Joint Compound Drying Time Slowing Your Project Down?

Posted by Matt Milos on Sep 24th 2018

The modern construction schedule is the key to profitability. We all know it whether or not we want to admit it. Unforeseen delays cost our projects more than just time, they are a loss of profit. One of the key areas those delays consistently rear their ugly head is the finish schedule (a.k.a. drying time).

The modern construction schedule is the key to profitability. We all know it whether or not we want to admit it. Unforeseen delays cost our projects more than just time, they are a loss of profit. One of the key areas those delays consistently rear their ugly head is the finish schedule (a.k.a. drying time).

Staying on schedule with finishes is directly related to profit.

In fact, one of the most common concerns I hear about are struggles in getting drywall mud to dry. In an effort to put hard numbers to the subject I came across in this article from the Drywall Finishing Council - Joint Compound Drying Time - The Impact of Environmental Conditions. (dwfc.org/publications) They publish their findings are as follows:

JOINT COMPOUND DRYING AS A FUNCTION OF TEMPERATURE & HUMIDITY

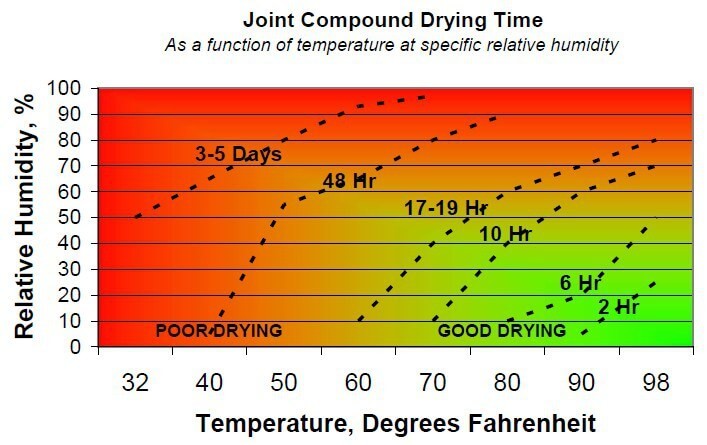

The purpose of this document is to illustrate how job environmental conditions affect the drying time of joint compounds. All water based joint compounds ranging from lightweight (less than 12lb/gal) to heavyweight (greater than 12 lb/gal) are affected by jobsite environmental conditions. When applied at the same thickness, drying time of a joint compound will vary depending on the temperature and relative humidity, with the latter being the dominant factor. High humidity conditions slow the evaporation of water which can delay drying of joint compounds for inordinately long periods of time.

The graph below visually presents how relative humidity along with temperature can have a profound effect on the drying time for a coat of joint compound at a 1/16 inch thickness. Second and subsequent coat applications may also be inferred by use of the same information.

Graph Reference

The color-coded graph provides an easy-to-interpret map of joint compound drying time ranges based on the relative humidity and temperature conditions present on a job. To estimate joint compound drying time, simply select and cross-reference a temperature and relative humidity range to determine approximate drying time per coat (1/16 inch nominal).

GOOD

Green shaded areas are environmental conditions that provide best drying.

FAIR

Yellow shaded areas are environmental conditions considered to be reasonable drying conditions. However, longer drying times - up to 48 hours between coats - are possible depending on temperature and humidity levels.

POOR

Red shaded areas are environmental conditions to avoid. Significantly longer drying times over 3 days, also known as poor or slow drying conditions exist. Such unfavorable temperature and humidity conditions can lead to finishing problems.

Changing Job Conditions and Drying

As the job atmosphere becomes more humid and saturated with water during the joint treatment operation drying time can increase. For example; at 55°F (with little ventilation), there can be as much as a 4X increase in drying time if room humidity elevates from 50% to 90%. Other atmospheric conditions at the jobsite can result in similar changes in drying time.

Copyright Drywall Finishing Council Incorporated. All Rights Reserved. www.dwfc.org

Increased humidity means increased delays.

The study does a fantastic job of laying out the need for controlling the climate during construction as it relates to finishing times. Here are some key takeaways:

- The finishing times used in this example are for ONE - 1/16"application. Applications thicker or subsequent coats only serve to compound and extend dry time further. By continuing to push in unfavorable conditions the increased drying time will only continue to compound the problem.

- Higher temperatures do not effect the drying time of finishing compound anywhere near to the extent that humidity does. For an on-time finish schedule, prioritize dehumidification rather than temperature.

- Finally, look again at the note in parentheses above (with little ventilation). Most construction projects have little to no ventilation at all, with no permanent HVAC system yet in operation. However, even if there is a system chances are it will struggle to overcome the increased load of construction. Permanent systems are just that, designed to deal with permanent occupancy and normal traffic. They are not designed to handle construction traffic and the excess moisture load that finishes put upon it. Air movement is your friend, and planning for this inexpensive item will save you all kinds of headaches.

Taking control of your schedule is easier (and less expensive) than you think. We would love to help you do just that.