Grinding and Dust Control: More Than Just “Because OSHA Says So”

Posted by Matt Milos on Nov 29th 2018

Grinding concrete and masonry will inevitably produce silica dust. You can't avoid it, but OSHA laws require you to do something about it.

Grinding concrete and masonry will inevitably produce silica dust. You can't avoid it, but OSHA laws require you to do something about it.

It's important to know that OSHA silica regulations are not just bureaucratic red tape, they address a real issue with a real impact on construction pros and their families. Addressing it, however, is surprisingly simple.*

Why does dust-control matter?

Silica dust is extremely dangerous when inhaled. The dust particles make small cuts on the inside of the lungs, making it harder breathe and increasing the risk of infection. Additionally, silica is a classified as a carcinogen, meaning it is capable of causing cancer. Unlike other construction hazards like injuries or chemical burns, silica takes time to do damage. Many pros didn't see the effects until later in life, but at that point it was often too late. Reducing silica dust now could save a worker's life in the long run.

DISCLAIMER: The following blog post simplifies what can be some very complex laws. This is meant to be a starting point for the tools you can use, but you should always cross-check your dust-control measures directly with OSHA law.

How can I lower silica dust while grinding?

The solution to most dust issues is actually quite simple: attach a shroud and hook up a HEPA vacuum**. Many handheld and walk-behind grinders already include a shroud to control the dust. Pair this with the appropriate HEPA vacuum and you are on your way to compliance with OSHA silica regulations. Note that both of these measures are mandatory.

HEPA vacuums have stronger filters than regular shop-vacs and are the only kind of vacuum equipped to properly filter out silica dust***. Many of our vacuums feature the Longopac system which ensures simple, dust-free bag changes. Others, like the Husqvarna DC5500 can handle demanding industrial settings that require a lot of power to keep up with dust production.

You can also use Personal Protective Equipment (PPE) to reduce silica intake.

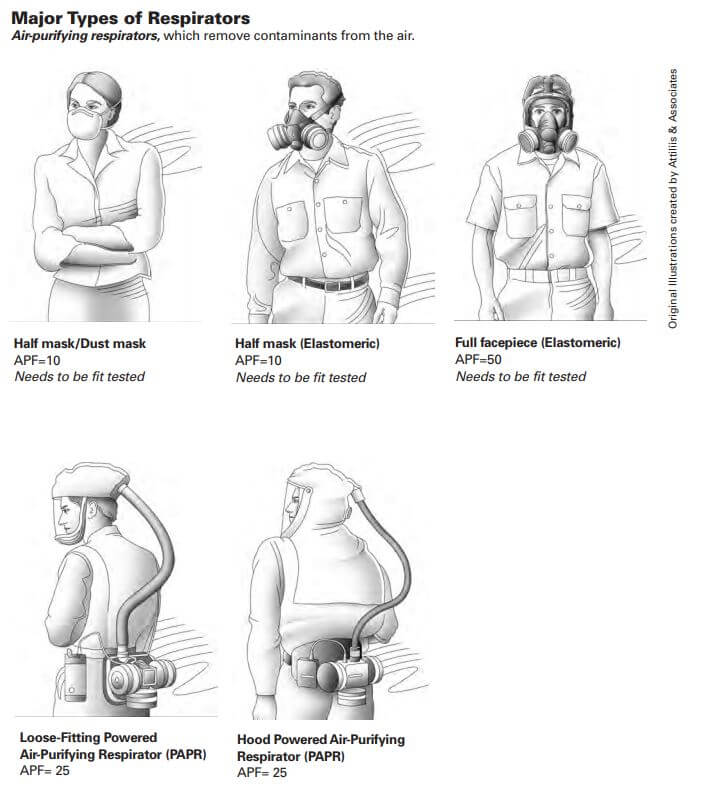

OSHA laws on PPE vary depending on the kind of grinding, length spent grinding, and whether it takes place indoors or outdoors. This is one of the trickier parts of dust-control and one worth reading up on in detail. Some cases require APF 25 or higher, while others require only APF 10. No matter what level of PPE required, this does NOT mean you can neglect using a dust shroud and HEPA vacuum. PPE needs to be used in combination with measures that keep dust levels under permissible OSHA levels. Below are some examples of different levels of PPE:

An important note: ventilating the area or using an air scrubber is not enough. The only way to stop workers from breathing in airborne silica is to take care of the dust at the point of contact.

Regulating silica is essential to keeping both you and your personnel healthy on site. If you have a question we didn't tackle here, feel free to get in touch on our contact us page!

*The following apply only to grinding (handheld or walk behind). Read about rules for cutting, drilling, and more here.

**You can also use a water-delivery system, but because the slurry creates a mess most opt for the vacuum option. OSHA regulations are different for wet-grinding.

***You cannot use a regular shop vac to collect silica dust. Only HEPA vacuums can properly filter the dust to OSHA standards. Our entire line of HEPA vacuums exceeds OSHA requirements.