Three Quick Tips for Successful Project Humidity Control

Posted by Matt Milos on Aug 22nd 2018

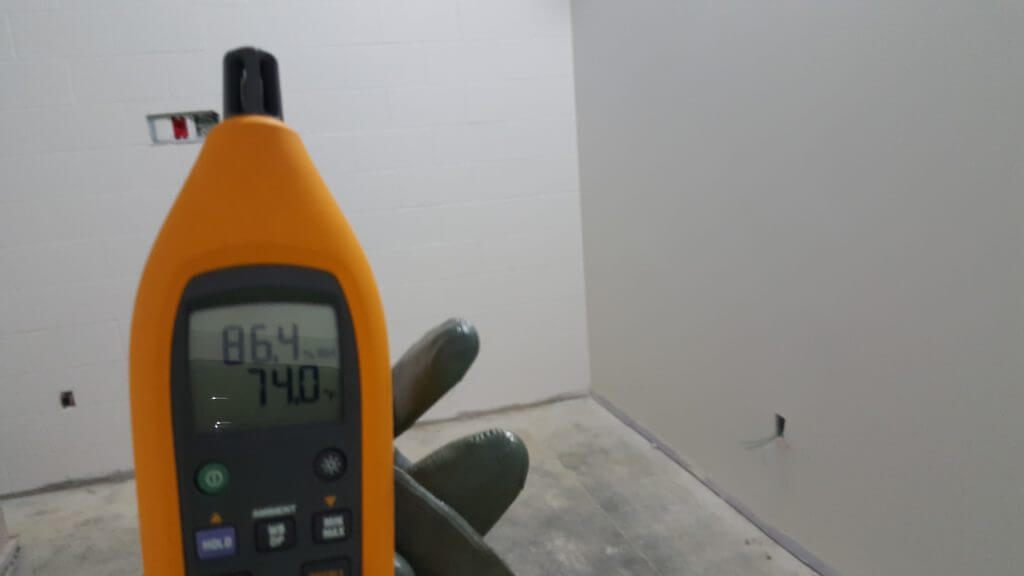

Many of us did not think winter was ever going to end this year. As the old saying goes, "If you are not happy with the weather in Ohio just wait 15 minutes." What that 15 minutes brought us this week is 3 out of 5 days with an ambient RH level above 90% with Tuesday topping over 94%. A rude awakening for sure, but as challenging as building in winter can be, these relative humidity numbers can have costly effects on your project if left unchecked. Judging from the number of times I have been contacted about this in the last couple of weeks I thought it might be helpful to post a list of what I consider to be the key areas to focus your attention for results by using construction dehumidifiers and air movers.

Construction Dehumidifiers Tip #1 - Make sure the area(s) that need to be controlled are as tight as possible. Much in the same way you would not expect your furnace to efficiently heat your house with the front door open, to condition a space and maintain a desired relative humidity level, the space needs to be under control.

Unnecessary openings invite wasted energy.

Construction Dehumidifiers Tip #2 - Volume calculations are very important. Dehumidifiers can be very effective in controlling humidity levels to prevent mold growth, maintain finish schedules, and preserve expensive woodwork, but in order to be successful, the right amount of equipment must be deployed.

The larger the space, the more equipment needed to control heat and humidity.

Construction Dehumidifiers Tip #3 - Not all dehumidifiers are created equal. The AHAM standard for reporting efficiency of dehumidification equipment is measured at 80 degrees F and at 60% RH. This is considered a baseline for comparing equipment. Most manufacturers will further test their equipment at saturation levels (90 degrees / 90% RH), these numbers show maximum performance that can be expected under those conditions. These extreme instances however are more drying operations than they are controlling operations and are therefore are less relevant to day to day operation. Make sure you are factoring in the correct performance level into your plan.

In addition to performance, power requirements should be studied. While most refrigerant dehumidifiers do not need a huge amount of electricity, the development and refinement of these pieces of equipment have in some cases cut in half the amps required to operate. When you start talking about large volume control on power starved projects, equipment that operates on 10 amps allow for greater flexibility than say one that operates on 16 amps.

Is your equipment up to the task?

Bonus Tip - One often overlooked easy add on for success are air movers. Drying is all about energy. The more energy you put into a system, the better results you will see. In addition, air movement makes dehumidifiers more effective and keeps stale air from stagnating. This can be particularly helpful in preventing spore development as well. "Barn fans" that are most commonly seen on job-sites are good but there are better ways. These fans are often large, need 15-20 amp service, and generally move 1,600-2000 cfm. The newer breed of air movers are about the size of a suitcase, require only 2.5 amps each, and move 3,000 cfm of air. Pairing a couple of these air movers with the correct dehumidifier results in an incredibly effective package that operates on only 15 amps total, efficient for sure.

Air movers can increase the efficiency of your equipment.

Mother Nature does not have to play havoc with your schedule while costing you time and money. Simply by defining a goal and devising an appropriate plan that fits your needs, you can easily keep your project on track without breaking your budget. If you need any help devising a plan for treatment, or could just use some help evaluating your situation please feel free to contact me, I am here to help. Thank you,

Heath Warner